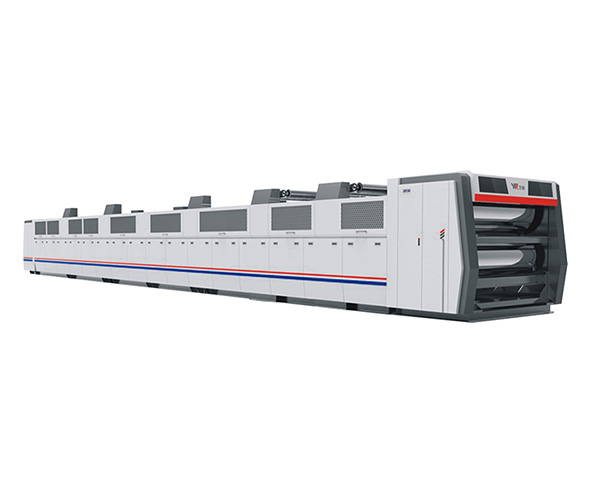

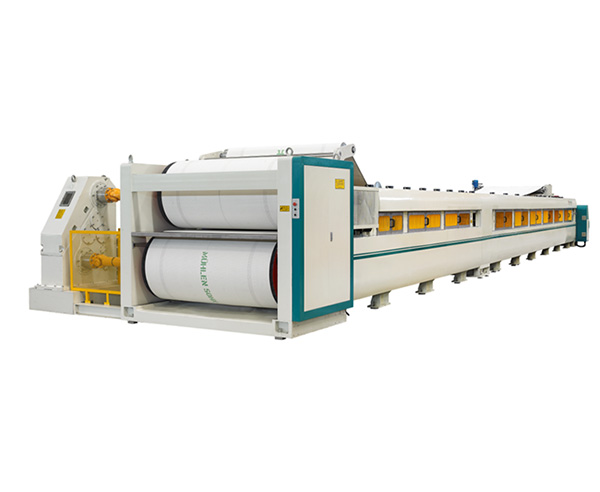

※Common Spec:

1, working width: 1600mm

2, Operation Direction: Left or right (decided by the workshop of customer)

3, Max machinery speed: 180m/min

4, Temperature requirement: 160—200℃ Steam Pressure: 0.8-1.3Mpa

5, Air pressure:0.6—0.9Mpa

6, Cool shaping length: 6.5m Heating plates amount:20 pieces

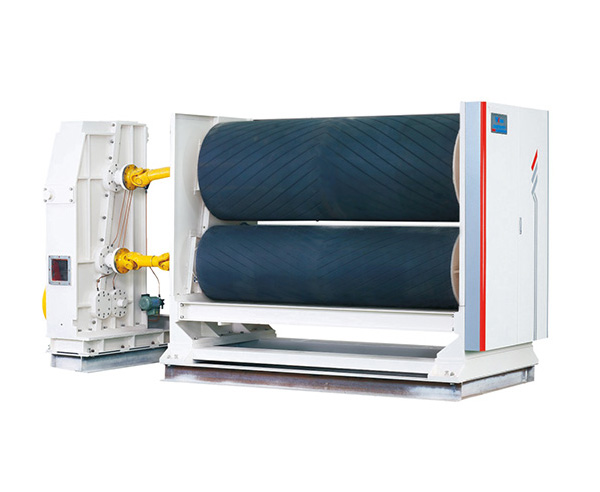

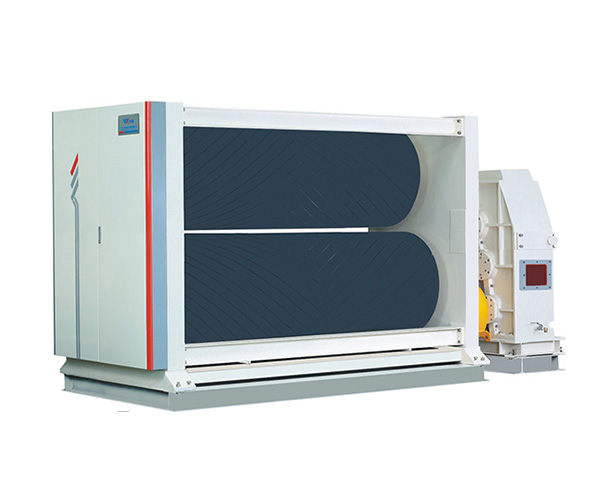

※Spec of the rollers’ diameter:

| Roller | ||

| 1, | Up drive roller | ¢850mm(Wrapped by anti-grinded rubber) |

| 2 | Down drive roller | ¢650mm(Wrapped by anti-grinded rubber) |

| 3 | Front driven belt roller | ¢318mm |

| 4 | Back Shaping Driven belt roller | ¢318mm |

| 5 | Belt Press roller | ¢70mm |

| 6 | Shaping Holder Roller | ¢85mm |

| 7 | Up Belt Tension roller | ¢185mm |

| 8 | Up belt correcting roller | ¢140mm |

| 9 | Down Belt Tension roller | ¢200mm |

| 10 | Down Belt Holder Roller | ¢140mm |

Note: All the surfaces of the rollers are grinded and then chromed plated.

※Spec of Motor:

Main Drive Motor: 75KW(variable frequency) Voltage: 380V 50Hz Continuous (S1) working Type

Hydraulic station motor: 2.2kw Voltage: 380V 50Hz Continuous (S1) working Type

※Spare Parts that need to buy from others and main materials:

| Main Parts’ Name | Band or Origin | Material |

| Main Frame | Tianjin Iron & Steel Group Co., LtdOr Laiyang Steel Co., Ltd | 400 or 300 Channel Steel and 125H steel |

| Heating Plates | Tianjin Iron & Steel Group Co., Ltd or Jigang Group Co., Ltd | Q235BConainer Plates |

| Main Drive Motor | Siemens | Frequency variable 75KW |

| Cotton Convey Belt | Shenyang Fuli | Thickness of cotton belt 9mm |

| Drain Valve | Beijing | |

| Electric Appliance | Siemens |