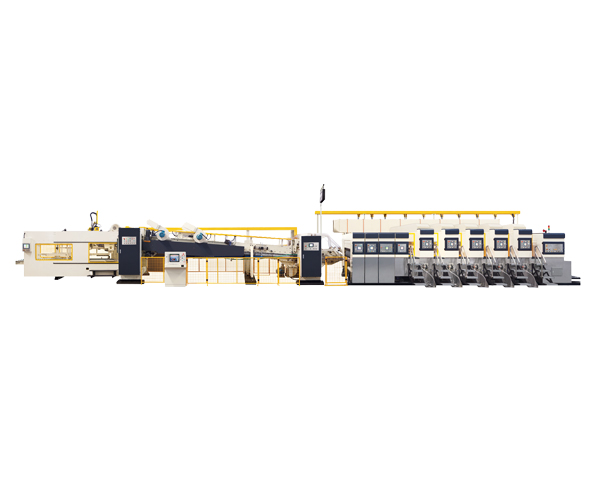

Features:

◆ Integrated CNC control system, troubleshooting, production.

management, remote maintenance.

◆ Quick printing plate mounting, motorized phase zero.

◆ Powerful dust remover, with anti-static bar, centralized dust collection, less ECT loss.

◆ High precious transfer structure with ceramics vacuum transfer wheel, good registration accuracy.

◆ Choose international brand electric components and transfer bearings, pass CE certification.

Main Console:

◆ Windows base CNC control system.

◆ Remote maintenance.

◆ Huge order saving.

◆ Trouble-shooting

◆ Optimized order memory.

◆ Production and order management.

◆ Available to connect with the customer internal ERP.

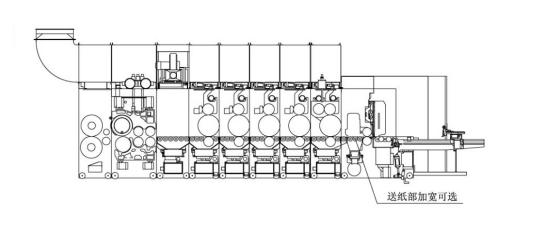

Feeding Unit:

◆ Operation can be controlled by both main console and each unit touch screen.

◆ Lead-edge feeding, adjustable air control, precious registration.

◆ Precious liner guideway lateral moving.

◆ Motorized side squaring and paper support.

◆ Powerful dust remover, with anti-static bar, centralized dust collection, less ECT loss.

Printing unit:

◆ Operation can be controlled by both main console and each unit touch screen.

◆ Top print, high precious transfer structure with ceramics vacuum transfer wheel, good registration accuracy.

◆ Quick printing plate mounting, motorized phase zero.

◆ Ink saving circulate system, safety ink taking, short ink alarm.

◆ Option: Double doctor blade.

Drying Unit:

◆ Operation can be controlled by both main console and each unit touch screen.

◆ Vacuum transfer, motorized gap adjustment.

◆ Energy saving dry section, hot air circulating,

settable temperature.

◆ Option: Infrared ray or UV dryers.

Slotting unit:

◆ Operation can be controlled by both main console and each unit touch screen.

◆ Liner guideway lateral moving device with universal cross joints.

◆ Pre-creaser, creaser slotting holder motorized gap control.

◆ Box height motorized control.

◆ Large displacement of middle knife.

Die-cutting Unit:

◆ Servo driven control.

◆ Up die-cutting, clean up scrap thoroughly, motorized die-cutting pressure adjustment.

◆ Die-cutting roll pneumatic self-locking device, smooth die-cutting.

◆ Sheet guide roll displacement motorized control, quick order change.

◆ C.U.E quick change die-cut anvil with grinding mechanism. Precious settable speed difference compensation, ensure die-cutting accuracy.

Waste remove Unit:

◆ Independent stripping unit.

◆ Belt transfer, angle adjustable fan assistant clean up scrap.

◆ Dual vibration roll, speed frequency invert control.

◆ Powerful fan clean up scraps.

Stack Unit:

◆ Stacker operate automatic or manually.

◆ Pneumatic lifting device for receiving arm , tightness degree adjustable.

◆ Different speed section type stacking, transfer belt inverter.

◆ Stacker platform lifting inverter control, protection device for lifting safety.

◆ Side square. Pneumatic stacker lifting.