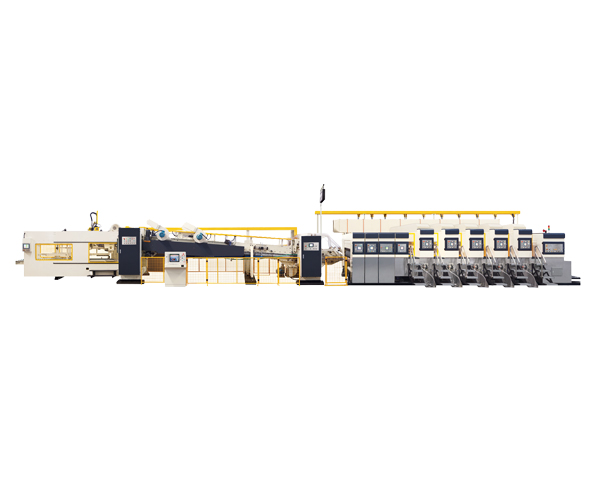

Main structure of machine

Feeding Section

1.Vacuum suction feeding to feed warping paperboard easily

2.Quality electromagnetic clutch and brake adpoted, feeding section controlled independently, operation easily

3.Stainless steel glue wheel adopted, long life and saving glue cost

4.Second creasing struction can impress again the paperboard which was not creased well

Gluing and Folding Section

1.Simpless structure and high reliability, glue quantity adjustable, cleaning easily

2.Creaser wheel adjustable, suit for 2-8mm thick paperboard

3.Imported quality rubber belt adopted, automatic folding

4.With paperboard rectify device and creasing rectify device

Counter and Stacker Section

1.Stacking and counting are simple and reliable

2.Digital control, operation easily and reliable. No-stop put in data and automatic counting

3.With rectification function

4.Paperboard counting and put out by pneumatic, stable and quickly

| Model | 2400 | 2800 |

| Max feeding | 900*2200 | 1200*2500 |

| Min feeding | 300*900 | 300*900 |

| Installation area | 11000*3000*1600 | 12500*3200*1600 |

| Weight | 5500kg | 6500kg |

| Power required | 11.5kw | 14.5kw |

| cardboard thickness | 3-5ply cardboard | |

| control method | PLC | |

Main electiric parts as follows

| No | name | brand |

| 1 | Touching screen | DELTA |

| 2 | PLC | PANASONIC |

| 3 | inverter | DELTA,TAIWAN |

| 4 | relay | OMRON,JAPAN |

| 5 | Photoelectric switch | HUGONG,CHINA |

| 6 | Switch power | MEANWELL,TAIWAN |

| 7 | Thermal overload relay | CHINT,CHINA |

| 8 | breaker | CHINT,CHINA |

| 9 | switch | CHINT,CHINA |

| 10 | contactor | SEIMENS,GERMANY |

| 11 | button | SCHNEIDER,FRANCE |