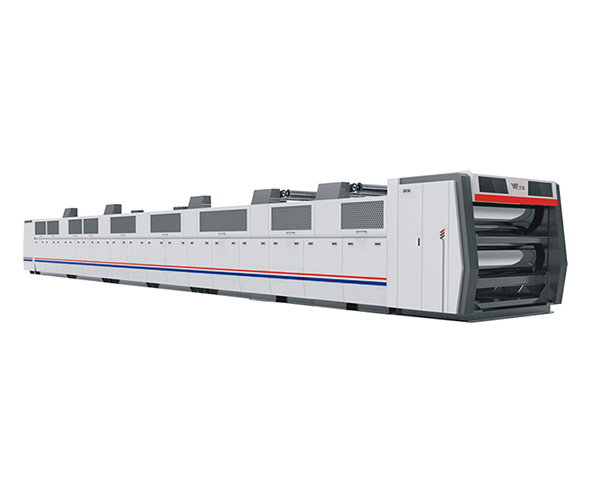

★The front and back feeding paper wheels all adopt the sun wheel

creasing way, deliver atable, pressure equality, not easy to press the

plate broken or cause bad jam.

★Precision adjustable no-gap gear, ensure the blade edge accurate mesh, run balance.

★Blade roller: high quality precision forging steel, equalization treatment, have good stability.

※Common Spec:

1, Max working width: 1600mm

2, Operation Direction: Left or right (decided by the workshop of customer)

3, Max machinery speed:180 m/min

4, Min paper width: 500mm

5, Max paper width: 9999mm

※Spec of the rollers’ diameter:

| Up drive roller | ¢215mm(Wrapped by anti-grinded rubber) |

| Down drive roller | ¢215mm(Wrapped by anti-grinded rubber) |

| Front down driven belt roller | ¢156mm |

| Back down Shaping Driven belt roller | ¢156mm |